Add to Cart

Why we design VMC-V855:

First of all, 850 two axes linear guideway model is the traditional one, with thick fuselage, and relatively small screw pitch, and relatively slow processing speed, generally 24m/min. 850 series is used for processing aluminum workpiece, steel workpiece and mold, with characteristic s of high rigidity but low efficiency.

Second, v85 three axes linear guide way model is popular series for processing aluminiun workpiece in recent years because of light and handy fuselage and high three axes moving speed, generally 48m/min. But when it process steel workpiece, it's rigidity is not enough, and its speed need to slow down.

However, now lots of customers receives include aluminium and steel, and usually it is batch orders. such as the automation module processing industry

For these customers, buying one of these two models is not enough for them. 850L is not high efficiency for aluminium parts and v85 is not rigid enough steel parts. And it is not high cost performance for buying both of them. So we launch a new model v855 which can meet customers'efficiency and rigidity requirements. And it's cost hasn't increased much.

So if you have parts with materials not only alumnium but also steel, you can consider our VMC-V855, which is with characteristics of high speed and high rigidy. One machine can do things that usually needs two machines to do. Truly save your money and time.

Updated points:

1. Improve its structure according to force analysis: Widen spindle box and column linear guidway mounting surface, Z axis increased to 6 slides, base and column with special big span structure, enhancing machine rigidity fully.

2. Oil pipe line design optimization, solenoid valve, oil pump, and others centralized visual design. Customers can see them all through transparent window in one time. Check all fast in one time if something wrong.

3. Equipped with high flow chip flushing system, multi-filter structure of water tank, meet requirements of high speed of chip removal. Reduced failure caused by pump blockage.

4. With characteristics of high feeding speed, high processing rotation speed.

Specification:

| Model | V855 | |||

| Travel | X axis travel | mm | 800 | |

| Y axis travel | mm | 540 | ||

| Z axis travel | mm | 540 | ||

| Distance between spindle and table | mm | 140-690 | ||

| Distance between spindle and column | mm | 590 | ||

| Table | Size | mm | 1000*500 | |

| Load | kg | 500 | ||

| T slot size | mm | 3-18-130 | ||

| Spindle | Taper | BT40 | ||

| Installment diameter | mm | Φ150 | ||

| Rotation speed | r/min | Belt 50-10000/Direct 12000/15000 | ||

| Three axis | X,Y axis motor output torque | N.M | 13.7/11 | |

| Z axis motor output torque | N.M | 22.5/20 | ||

| X,Y axis motor rate | KW | 2.0/1.8 | ||

| Z axis motor rate | KW | 3/3 | ||

| Cutting feed | m/min | 15 | ||

| Rapid feed | m/min | 48/48/48 | ||

| Arm type Tool magazine | Tool capacity | T | 24 | |

| Maximum diameter/ length/ weight of tool | mm/mm/kg | 80/200/8 | ||

| Maximum diameter of tool (no tool) | mm | 150 | ||

| Tool change time (T-T) | s | 2.8 | ||

| Accuracy | Positioning accuracy (X/Y/Z) | mm | 0.006/0.006/0.006 | |

| Repeat positioning accuracy (X/Y/Z) | mm | 0.005/0.005/0.005 | ||

| Other | Dimension | mm | 2450*2535*2660 | |

| Power capacity | KVA | 15 | ||

| Weight | kg | 5200 | ||

| Standard accessories: 1. Mitsubishi/ Fanuc controller system | Optional accessories: 1. Screw type conveyor |

Application Industry:

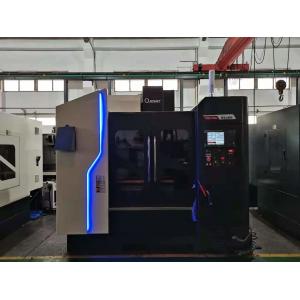

Overview:

Package:

1. Our wooden pallet (wooden case) would fumigate and can get fumigation certificate.

2. Our package will be very careful for the parts, accessories for the machine.

Every part, accessory that need to be removed from machine, we will use pearl cotton and transparent film to pack them.

And make a note of them.